conventional hardness test vickers|vickers hardness test chart : sourcing This chapter presents different types of hardness test method, and calibration of testing machines (both direct and indirect method). Conventional static hardness methods (Brinell, Rockwell and Vickers) and dynamic Leeb rebound hardness with corresponding uncertainty calculation is discussed in this chapter. Cars - GTA San Andreas SA_DIRECT RENDER 3.0 Mod - G.

{plog:ftitle_list}

WEBRead Jinx - Chapter 39 | ManhuaScan. The next chapter, Chapter 40 is also available here. Come and enjoy! Physical therapist Kim Dan has been down on his luck for as long as .

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h. This chapter presents different types of hardness test method, and calibration of testing machines (both direct and indirect method). Conventional static hardness methods (Brinell, Rockwell and Vickers) and dynamic Leeb rebound hardness with corresponding uncertainty calculation is discussed in this chapter.

ferrex feuchtigkeitsmessgerät bedienungsanleitung

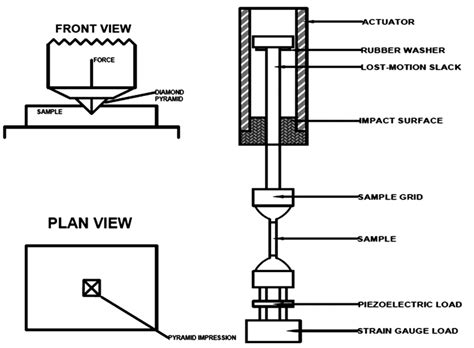

In a conventional hardness test, . formation was inspected and classified into four different types of cracks. Microhardness test was performed using a Vickers hardness test. Higher frequency of . The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface.

The conventional Vickers hardness test employs the length of the diagonals of the indent, for the calculation of the area after the load had been released and ignores the difference in the pile-up .Conventional hardness testers, like Rockwell, Brinell or Vickers machines, require the test piece be brought to the testing device; but this is not always possible. Portable testing devices have been developed that permit in-situ hardness measurements thus offering quick and economical supplements to conventional, stationary testing machines.Loading method using Load-cell instead of the conventional weight method. By adopting the Load-cell load system, multi-stage load switching is possible. The load switching work has evolved from the conventional dial operation to a smooth touch panel operation. Any load can be selected when ordering. (within the minimum to maximum load range)

The Vickers hardness test was developed by George E. Sandland and Robert L. Smith at Vickers Ltd. in the year 1921, as an alternative to the Brinell method to determine the hardness of materials. This Vickers hardness test is usually easier to use compared to other hardness tests. . Conventional (Macro) Hardness Range: Used for standard .Vickers hardness testing of small areas. Equipped both with the latest optical system. . conventional illumination units. Automatic: turret mechanism: The positions of the indenter and the objective : lens can be automatically switched using touch panel operation (can also be .

The FALCON 400 improves on the conventional hardness testing methods by focusing on elimination of user influence on the test results. The advanced force sensor technology utilizes an electronically controlled loadcell closed loop system with force feedback to achieve absolute accuracy, reliability and repeatability, on all of the forces used . The most conventional indenters used are Vickers and Knoop pyramidal indenters that lead to different Hardness numbers, Vickers hardness HV and Knoop hardness HK respectively. In conventional hardness testing, hardness of materials is defined as the ratio between the applied load P and a representative contact area between the indenter and the . An extensive comparison between the conventional Vickers hardness at 500 mN and indentation hardness measured with Vickers indenters at 500 mN is presented for up to 20 different materials and for .Different techniques are used to quantify material characteristics at smaller scales. Measuring mechanical properties for materials, for instance, of thin films, cannot be done using conventional uniaxial tensile testing. As a result, techniques testing material "hardness" by indenting a material with a very small impression have been developed to attempt to estimate these .

The most conventional indenters used are Vickers and Knoop pyramidal indenters that lead to different Hardness numbers, Vickers hardness HV and Knoop hardness HK respectively. In conventional hardness testing, hardness of materials is defined as the ratio between the applied load P and a representative contact area between the indenter and the . Lastly conventional high-temperature Vickers hardness testing was performed to verify HTIIS experimental results for the same nine carbon steels. AVK-HF (Akashi, Japan) was used for conventional Vickers hardness testing at 25 °C, 200 °C, 400 °C and 600 °C at the Technology Innovation Center for Fine Ceramics (FCTIC, Korea).

A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, . During the course of the instrumented nanoindentation process, unlike conventional hardness or microhardness testing which only record the load applied, the depth of penetration of the indenter in the .

In today’s international commerce, conventional hardness testing is almost exclusively conducted in compliance with the Rockwell, Brinell, Vickers and Knoop hardness test methods specified by either ASTM-International (ASTM) [1] or the International Organization for Standardization (ISO) [2]. These test methods specify requirements for the .DOI: 10.1016/J.JEURCERAMSOC.2017.02.014 Corpus ID: 136205278; Comparison of conventional Knoop and Vickers hardness of ceramic materials @article{Ghorbal2017ComparisonOC, title={Comparison of conventional Knoop and Vickers hardness of ceramic materials}, author={Ghailen Ben Ghorbal and Arnaud Tricoteaux and .The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

The Vickers hardness test utilises a diamond pyramid-shaped indenter to create a small impression on the material's surface. Taking into consideration the weight of the load, the size of the indentation is measured using a microscope. . where other conventional hardness tests might be impractical or not feasible. However, it's important to .The paper presents a novel algorithm for detection and measurement of indentations in Vickers hardness testing images, within a specific case of applied research on material quality evaluation based on image processing. The algorithm performs image segmentation by binarization, morphological filtering, and region growing, where the binarization threshold is .The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test. . (conventional hardness range) HV 5. Diamond pyramid 136 .

Abstract An extensive comparison between the conventional Vickers hardness at 500 mN and indentation hardness measured with Vickers indenters at 500 mN is presented for up to 20 different materials and for three different instruments. Additionally, the indentation modulus is compared to Young’s modulus, which was measured with alternative methods or .We evaluate Vickers hardness and true instrumented indentation test (IIT) hardness of 24 metals over a wide range of mechanical properties using just IIT parameters by taking into account the real contact morphology beneath the Vickers indenter. Correlating the conventional Vickers hardness, indentation contact morphology, and IIT parameters .4. Significance and Use 5.3 Summary of Test Method—In conventional workbench hardness testing like Brinell or Vickers testing according to Test Methods E10 and E384, the hardness value is determined optically by the size of the indentation in the material generated by a certain test load, after the indenter has been removed.

computed on the basis of the crack lengths, the indentation load, the hardness, the elastic modulus, the indentation diagonal size, and an empirical fitting constant. This method has the appeal that it uses conventional hardness equipment, uses a very small test piece, and does not require elaborate precracking or testing equipment.

Abstract This paper describes the process used by the Consultative Committee for Mass and Related Quantities - Working Group on Hardness (CCM-WGH) of the International Committee of Weights and Measures (CIPM) to develop international definitions of the conventional Rockwell, Brinell, Vickers and Knoop hardness test methods, for use by the .The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; and the same indenter (a pyramidal diamond) can be used for all materials, irrespective of hardness. .

vickers hardness testing machine diagram

7. Dominicanenklooster Zwolle. 54. Religious Sites. This Dominican convent is a place to marvel and contemplate. This neogotic complex is openend in 1901 and consists of a .

conventional hardness test vickers|vickers hardness test chart